The packaging industry is undergoing a rapid transformation, driven by evolving consumer demands, sustainability concerns, and the relentless pursuit of efficiency. This transformation is heavily reliant on advanced automation, and at the heart of this lies the performance and reliability of motion control components, particularly gear motors. New-generation gear motor manufacturers are emerging as key players, offering innovative solutions that are redefining packaging equipment capabilities. This article explores the current application trends of these manufacturers, highlighting the technological advancements driving efficiency, precision, and adaptability in the packaging sector, and connects them to broader trends like Industry 4.0 and the circular economy.

The packaging industry has long been striving for increased automation to meet rising production volumes and reduce labor costs. The COVID-19 pandemic further accelerated this trend, forcing companies to prioritize contactless processes and invest in robotics and automated systems. According to a recent report by MarketsandMarkets, the global packaging automation market is projected to reach $46.8 billion by 2027, growing at a CAGR of 10.7% from 2022. This growth is fueled by the need for enhanced hygiene, reduced human contact, and improved operational efficiency.

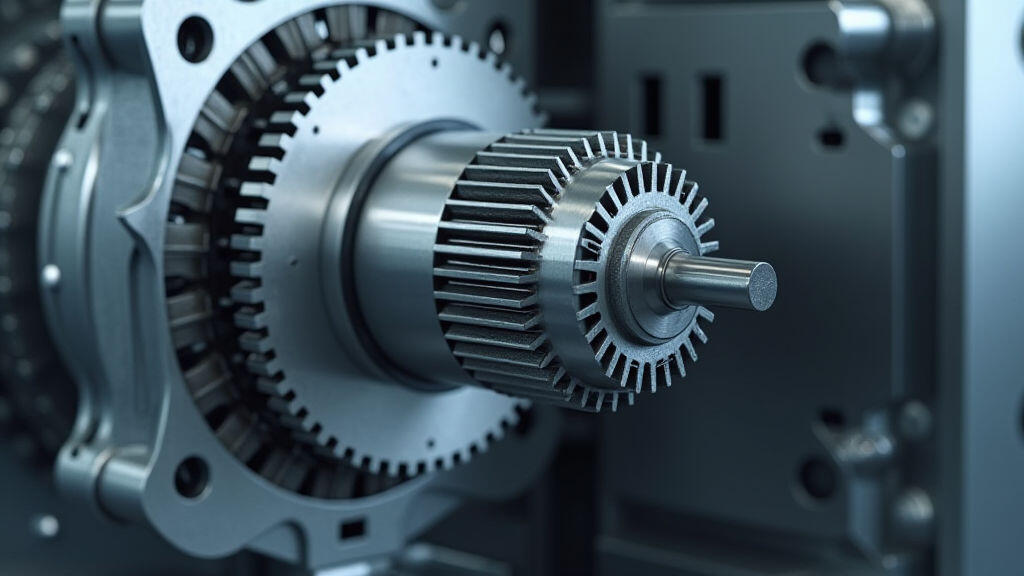

Gear motors are integral to a wide range of packaging machinery, powering conveyors, filling machines, sealing equipment, and labeling systems. However, traditional gear motors often fall short in terms of precision, energy efficiency, and adaptability to the increasingly complex demands of modern packaging lines. This is where the innovation from new-generation manufacturers comes into play.

Several key technological advancements are shaping the application landscape of gear motors in packaging:

1. High-Precision Gearboxes & Servo Motors: Traditional gearboxes often suffer from backlash – a small amount of play in the gears – leading to inaccuracies in positioning and motion. New-generation manufacturers are deploying advanced manufacturing techniques like precision grinding and advanced materials to minimize or eliminate backlash. Servo motors, coupled with highly precise gearboxes, enable incredibly accurate control over motor speed, position, and torque. This is vital for applications like precise product positioning for filling or intricate labeling operations. These systems also readily integrate with Programmable Logic Controllers (PLCs) and other automation systems as part of the Industry 4.0 ecosystem.

2. Brushless DC (BLDC) Motor Technology: BLDC motors offer superior efficiency, longer lifespan, and reduced maintenance compared to brushed DC motors. They are becoming increasingly popular in packaging applications due to their ability to handle high torque requirements with optimized energy consumption. Furthermore, BLDC motors are inherently more reliable in harsh environments, a common requirement in packaging plants where dust and vibrations are prevalent.

3. Integrated Motor-Gearbox Solutions: Instead of purchasing motors and gearboxes separately, manufacturers are increasingly offering integrated solutions. This simplifies system design, reduces integration time, and improves overall system performance. This approach leads to optimized performance and reduced mechanical complexity, crucial for space-constrained packaging machinery.

4. IoT Integration & Predictive Maintenance: The Internet of Things (IoT) is transforming industrial equipment, and gear motors are no exception. New-generation manufacturers are embedding sensors into gear motors to collect data on performance metrics like speed, vibration, temperature, and torque. This data can be transmitted to a cloud platform for analysis, enabling predictive maintenance and preventing costly downtime. For example, by analyzing vibration patterns, potential bearing failures can be detected before they occur, allowing for proactive repairs. MES-Drive, for instance, offers a comprehensive IoT platform for monitoring and optimizing gear motor performance.

5. Energy-Efficient Designs: With increasing pressure to reduce energy consumption and carbon footprint, manufacturers are designing gear motors with energy efficiency in mind. This includes optimized gear geometries, advanced lubrication systems, and regenerative braking capabilities. Energy-efficient gear motors can significantly reduce operating costs and contribute to a more sustainable packaging process.

These technological advancements are translating into tangible improvements across various packaging equipment types:

Conveyors: Gear motors are used to drive conveyors, and new-generation designs offer smoother, more controlled motion, reducing product damage and improving throughput. Variable frequency drives (VFDs) are often integrated to provide precise speed control based on filling or sealing requirements.

Filling Machines: Precise and consistent filling is critical in packaging. High-precision gearboxes and servo motors ensure accurate dispensing of liquids, powders, and granular materials. The integration of vision systems allows for dynamic adjustments to filling parameters based on product characteristics.

Sealing Equipment: Reliable and consistent sealing is essential for product integrity. New-generation gear motors provide the torque and control needed for various sealing methods, including heat sealing, ultrasonic sealing, and induction sealing. Precise control minimizes material waste and ensures a secure seal.

Labeling Systems: High-speed labeling requires accurate positioning and reliable motion control. Gear motors enable precise label placement and alignment, even on complex product shapes. The integration of sensors and feedback systems ensures accurate label application.

Cartoning Machines: Cartoning, the process of forming boxes, relies heavily on precise gear motor control. Modern gear motor solutions ensure reliable and efficient box formation, minimizing material waste and maximizing production speed.

The packaging industry is increasingly focused on sustainability. New-generation gear motors contribute to this effort through:

Reduced Energy Consumption: Energy-efficient designs minimize the carbon footprint of packaging operations.

Extended Equipment Lifespan: Reliable and durable gear motors reduce the need for replacements, minimizing waste.

Smart Maintenance: Predictive maintenance reduces unplanned downtime and extends the life of equipment.

Optimized Material Usage: Precise control in filling and sealing processes minimizes material waste.

The movement towards a circular economy further emphasizes the importance of durable and efficient equipment. Gear motors that contribute to longer equipment lifecycles and reduced energy consumption align directly with the principles of the circular economy.

New-generation gear motor manufacturers are at the forefront of innovation in the packaging equipment industry. By embracing advanced technologies like high-precision gearboxes, BLDC motors, IoT integration, and energy-efficient designs, they are enabling greater efficiency, precision, and adaptability in packaging processes. The convergence of these innovations with broader trends like Industry 4.0 and the circular economy positions these gear motors as vital components for the future of packaging. As businesses strive to meet evolving consumer demands and embrace sustainable practices, the role of these innovative gear motor solutions will only continue to grow. MES-Drive, with its commitment to advanced technology and comprehensive solutions, is well-positioned to lead this evolution, empowering packaging companies to achieve new levels of performance and efficiency in a rapidly changing market.

Leave A Reply

Your email address will not be published. Required fiels are marked